Description

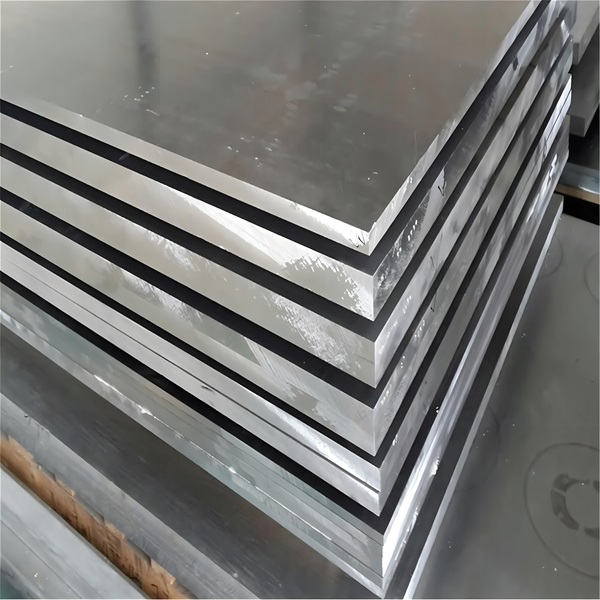

Best Aircraft And Aerospace Aluminum Alloy Sheets

Aerospace aluminum alloy sheets, also known as aviation aluminum plate, is a high-strength, high-hardness aluminum plate that is frequently used in the production of structural elements for aircraft and other applications needing extreme durability and strength.

Features of Aerospace Aluminum Alloy Sheets 7175 T351:

- Composition: The primary constituents of 7175 T351 aviation aluminum plate are titanium, magnesium, zinc, and aluminum, with around 7.5% of aluminum content coming from other elements.

- Strength and hardness: 7175 T351 aviation aluminum plate has great strength and hardness because of its unique composition and heat treatment method. It has a high degree of hardness and a tensile strength of above 520 MPa.

- Resistance to corrosion: Following a specific surface treatment, 7175 T351 aircraft aluminum plate has strong resistance to corrosion and is able to endure the effects of a variety of hostile conditions.

- Processing performance: 7175 T351 aviation aluminum plate has good processing performance in extruded aluminum profile factory and can be made into parts of various shapes and sizes through cutting, bending, drilling and other processing processes.

- Application sectors: 7175 T351 aviation aluminum plate is widely used in the aerospace, military, automotive, and other fields to manufacture critical components such aircraft fuselages, wings, and landing gears because of its exceptional performance.

7175 T351 aircraft aluminum plate, to put it briefly, is a premium, high-performing aluminum plate material that can satisfy a range of demanding application scenarios. The popular aerospace aluminum alloy are:

- 7075 T651 2324 T3/T351J

- 7150 T7751 2024 T3

- 7085 T7651 2524 T351

- 7050 T7451 2017A T4/T451J

- 7055 T7751 Alcad 2024 T3

Aerospace aluminum alloy sheets in bulk quantity

How to Weld 7175 T351 Aerospace Aluminum Alloy Sheets and Plate?

For a strong and dependable weld, welding 7175 T351 aerospace aluminum alloy sheets needs to be done precisely and carefully. The procedures for welding 7175 T351 aircraft aluminum plate are as follows:

- Safety precautions: Make sure you have the required safety gear, such as a helmet, welding gloves, and protective clothes, before beginning the welding process. To eliminate any dangerous fumes, make sure you are working in a well-ventilated environment or utilize a fume extraction device.

- Set Up the Workpiece: Using a wire brush or chemical cleaner, thoroughly clean the metal plate to get rid of any dirt, grease, or oxide coatings and custom aluminum profile manufacturer use. Before welding, make sure the plate is totally dry.

- Choose the Correct Welding Technique: TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), and laser welding are some of the welding techniques that are appropriate for welding aluminum. Because TIG welding is precise and controller, it is typically chosen for aerospace applications.

- Set Up the Welding Machine: Modify the welding machine’s parameters based on the aluminum plate’s thickness and the kind of welding technique you’re employing. Refer to the manufacturer’s instructions to find out the precise settings needed to weld 7175 T351 aluminum.

- Get the Weld Joint Ready: Choose the kind of joint that needs to be weld, such as a T-joint, lap joint, or butt joint. Make sure the aluminum plate’s edges are appropriately chamfered or beveled to allow for improved penetration and fusion during welding.

- Welding Technique: To begin, angle the TIG torch or MIG gun off the vertical plane by 10 to 15 degrees, directing the heat onto the thicker part of the joint. To ensure adequate fusion and penetration, maintain a constant travel speed and move the torch or gun along the joint in a controlled manner.

Non Destructive Testing Techniques in Aerospace Aluminum Alloy Sheets

Examine the weld visually when it is finished to look for any flaws like cracks or porosity. To verify the quality of the weld, you can also use non-destructive testing techniques like dye penetrant or ultrasonic testing.

After-Weld Handling permit the weld to naturally cool down to room temperature. If needed, you can use a grinder or file to remove any extra weld material after it has cooled.

Remember, welding 7175 T351 aerospace aluminum alloy sheets plate requires expertise and experience. If you are not confident in your welding skills, it is recommended to seek the assistance of a professional welder or welding engineer.

Owing to its excellent physical performance, aluminum plate is widely utilize in a variety of industries. Some of which include:

| Industry | Alloy |

| Aerospace | 7075 T651 2324 T3/T351J 7150 T7751 2024 T3 7085 T7651 2524 T351 7050 T7451 2017A T4/T451J 7055 T7751 Alcad 2024 T3 |

| Ship Building | 6082 T6/T651/Tl12 5754 H112 5052 H32/0 5083 H321/H116/H112/0 5086 0/H116 |

| Automotive | 6016 T4/T4P 5182 0 5754 0 6014 T4/T4P 6111 T4/T4P 7075 T4 6451 T4/T4 |

| Foil Stock (Coil) | 1235 H14/H16 8011 H14/H16 8079 H14/H16 8021 H14/H16 |

| Transportation, Construction, Hardware, Bottle Cap, Containers | 1060 H14/H16/H24/H26/0 6063 T4/T6/T651 3003 0/H1x/H2x 6061 T4/T6/T651 5052 H2x/H3x/0/H111/H112 6082 T4/T6/T651 5083 H3x/H112/H111/0 8011 H14/H16 5086 H3x/H112/H111/0 5182 0/H111/H112/H34 5454 0/H111/H112/H32 |

| Laptop, Ipad, Mobile Phone, 3C Material, Anodizing | 5252G H32/H34/H36 6061G T4/T6/T651 6063G T4/T6 5052 H32/H34/H36 5182 H34 |

| Can Body, Can End, Tap-Strip | 3004 H19 5182 H19 3104 H19 5052 5182 H48/H19 |

| Mold and Machinery | 2024 T351 6061 T651 5052 0/H111/H112 6063 T651 5083 0/H111/H112 7075 T651 6082 T651 |

Certification :IRIS,ISO9001,ISO14001,Aerospace Grade AS9100.