Description

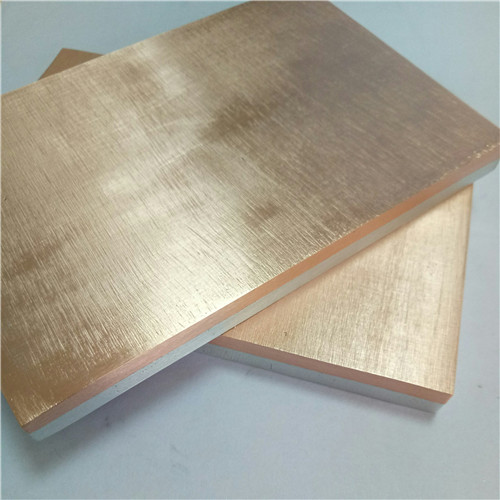

Double Sided Copper Clad Aluminum Plate Sheet

A double-sided copper clad aluminum plate is refer to as copper-clad or copper-based copper-clad plate. It is construct from composite aluminum alloy and copper plate using processing technology, using copper-clad plate and aluminum alloy plate as the basis materials.

The advantages of aluminum, such as its light weight, good toughness, plasticity, and electrical conductivity. The outstanding electrical conductivity, thermal conductivity, and corrosion resistance of copper, are combine in this type of plate.

Copper-clad aluminum plates are widely employ in several sectors. It is widely utilize in computers, communications, consumer electronics, and other industries in the electronics and communications industry. It can be used as a high-performance substrate for circuit boards to build high-reliability circuit boards.

Copper Clad Aluminum Plate Sheet Heat Sink for LEDs

It can also be used as a heat sink for LEDs, enhancing their ability to dissipate heat and extending their lifespan. In order to improve adhesion, copper and aluminum checkered plate typically need surface treatments during manufacture, such as pickling, alkali washing, and electrolytic treatment, before being coated.

In order to create a solid bond between the copper and aluminum plates under high pressure and temperature settings, the coating process frequently involves a lamination process. To further enhance its qualities, the copper clad aluminum plate may then go through heat treatments like annealing and solution treatment.

Copper-clad aluminum laminate has several benefits, but because copper and aluminum have distinct chemical characteristics, it can also induce electrochemical corrosion and be challenging to manufacture, requiring advanced processing technologies and equipment.

| Aluminum Plate Grade | Copper Plate Grade | Size |

| 1050 1060 1070 LF21 L2 | ASME SB 171 C70600, C71500, C71520 ASME SB152 C10200, C10400 C10500, C1100 GB/T 5231 T1 GB/T 2040 T2, T3, TU1 BFe30-1-1 | TK: Base plate:7-300mm clading plate:1-25mm W<5000mm L<15000mm |

A composite material with exceptional performance and a broad range of applications. Copper wrapped extruded aluminum profile factory is used extensively in the electronics, communications, LED manufacture, and other areas.

What particular uses does copper clad aluminum plate have in the communications and electronics industries?

1. Circuit board substrate

Using the superior conductivity of copper and the lightweight characteristics of copper clad aluminum plate can be utilized as high-performance circuit board substrates, satisfying the requirements of the circuit board for effective heat dissipation, high conductivity, and lightweight design.

The production of circuit boards for computers, communication devices, and consumer electronics. Especially dependent on this since it can increase the equipment’s stability and operational efficiency.

2. High frequency circuit

Copper-clad aluminum plates, with their lower dielectric constant and dielectric loss, can improve signal transmission quality and stability in high-frequency circuits by reducing delays and distortions in signal transmission.

As a result, it is frequently used to create high-frequency circuit boards, including those for microwaves, radio frequencies, and other frequencies. These circuit boards are also widely employed in other industries, such as radar systems, satellite communications, and wireless communications.

3. Electromagnetic shielding

Aluminum panels covered in copper offer high electromagnetic shielding qualities and can successfully shield electronic equipment from electromagnetic radiation and interference copper and aluminum conduct electricity. It is frequently utilize as an electromagnetic shielding material in communication equipment manufacturing. To increase the equipment’s electromagnetic compatibility and dependability.

4. LED heat dissipation

When LED bulbs are operating, they produce a lot of heat. An LED with inadequate heat dissipation will have a shorter lifespan and perform worse.

Copper clad aluminum plate can be use as a radiator material for LED lamps to increase the heat dissipation effect of LED lights and prolong their service life. Because of its strong thermal conductivity and heat dissipation performance.

Aluminum disc circle sheets covered in copper can also be use to create electrical parts like inductors and capacitors, as well as parts for communication devices like filters and antennae. It has several potential applications in various domains due to its superior mechanical and electrical qualities.